5-15 HP Two-Stage Oil-Free Piston Compressors

Features

5-15 HP Two-Stage Oil-Free Piston Compressors

Features

Built with a dry sump design and unique suction through crankcase design, this product meets the requirements of industries that need quality air without contamination like medical complexes, and food processing.

Applications

- Oxygen/Nitrogen generation plants

- Laboratories

- Research facilities

- Pharmaceutical industry

- Food processing and packaging

- Electronics production

- Ozone generation

- Printing equipment

- Fermenters

- Applications that are zero tolerant to oil in compressed air

Key features

- Oil less compressor with a unique suction through crankcase design

- Designed for industrial duty cycles

- Slow running speed for lesser wear and tear

- Air receiver coated internally for corrosion resistance

- Base mounted and receiver mounted variants available

- PTFE coated pistons, rings and sealed bearings for the lubrication of friction parts

1-4 HP Single-Stage Direct Drive Oil-Free Piston Compressors

Features1-4 HP Single-Stage Direct Drive Oil-Free Piston Compressors

Features

ELGi offers 1-4 HP Oil-free compressors to its customers who need small quantities of oil-free air to work with their sophisticated equipment like dental chairs and laboratory equipment. Designed for light duty applications, these compressors are of dry sump design ensuring compressed air delivery without oil contamination.

Applications

- Dental

- Fermenters

- Gas, Liquid and Ion Chromatography

- Food Processing

- Small, Sophisticated Laboratory Equipment

Key features

- Compact size, direct drive

- Durable aluminium body

- Piston rings of unique design

- Robust motor

- Reed valve

- Aluminium cylinder head and cylinders with deep fins

- Tropicalised

- Handle with rubber grip

- Wide network

3-40 HP Single and Two-Stage Industrial Piston Compressors

Features3-40 HP Single and Two-Stage Industrial Piston Compressors

Features

The ELGi Industrial single & two stage compressors are known for their reliability and performance, making them the preferred choice for industrial applications. Select models are available in base mounted versions.

Applications

- Automotive garages

- Wood working

- Small & medium fabrication units

- Pneumatic tools

Key features

- Zero leaks ensured by the use of leak proof fittings

- Designed for industrial duty cycles

- Slow running speed for lesser wear and tear

- Twin sided belt guards for safety and meeting OSHA standards

- Products available in single and two stages

1-3 HP Single-Stage Belt Drive Piston Compressors

Features

1-3 HP Single-Stage Belt Drive Piston Compressors

Features

The Single-Stage Belt Drive Reciprocating Compressors are designed for continuous duty application. These single-stage cylinder belt driven reciprocating compressors are reliable workhorses and can generate up to 10 bar g pressure suitable for most of the industries and automotive applications

Applications

- Concrete batch plants

- LPG dispensing units

- Utility air in petrol pumps

- Garages

- Small manufacturing workshops

Key features

- Single stage belt driven compressors

- Slow running speeds

- Models available in 45L, 100L and 160L receiver versions

- Single and three phase motor options available

1-2 HP Single-Stage Direct Drive Piston Compressors

Features

1-2 HP Single-Stage Direct Drive Piston Compressors

Features

The ELGi Vayu is portable and meets the requirements of small air. These compressors are handy for light duty applications like spray painting.

Applications

- Tyre vulcanising

- Spray painting

- Pneumatic tools

- Cycle shops & garages

- Small machine shops & fabrication workshops

- Community projects and more..

Key features

- Built-in thermal overload relay for motor protection

- Motor withstands wide voltage variation – 180V to 230V

- Models available in 1 -2 HP with 45L, 100L and 160L tanks

- Plug and play system

- Portable and mounted on wheels for easy maneuvering

3-20 HP ELGi’s High Pressure Piston Compressors

Features3-20 HP ELGi’s High Pressure Piston Compressors

Features

The high pressure range of compressors is suitable for usage in the range of 30-40 bar for applications like engine starting, circuit breakers and marine applications.

Applications

- Plastic & packaging industry

- Circuit breaking

- Thermal power projects

- Genset starting

- PET blowing

Key features

- Sealed safety valves for operational safety

- Slow running speed

- Efficient cooling system with deep finned cylinders and interstage/afterstage coolers

- Proven design backed by more than 3 decades of experience

Custom Built Compressors

Features

Custom Built Compressors

Features

ELGi builds custom built compressors for various applications like mining, diesel engine starting, hydel and concrete pumps.

Key features

- Designed to fulfill specific requirements like motors of specific voltages, customized control panels, product color and finish to meet customer requirements, provision of additional safety features like low oil switch and hooter/alarm

- Custom built to meet customer’s application requirements

EN Series Screw Compressors 2.2 to 75 kW

Features

EN Series Screw Compressors 2.2 to 75 kW

Features

ELGi’s EN Series screw compressors are designed to encapsulate all functional components of the compressor within a common housing. With a small footprint, high reliability and low maintenance requirements, these compressors are ideal for industrial applications where size, efficiency and cost matter.

Applications

- Textiles

- Food processing

- Paper

- Automotive

- Small machining and fabrication workshops

Key features

- Energy efficient air end

- Compact footprint and low running noise

- Reliable and low running cost

- Models available as base/mounted variants and also with side mounted drier

- 2.2kW to 5.5kW are available with 220L receiver and 7.5 to 15kW are available with 270L receiver

- Easy monitoring of system parameters with user friendly neuron controller

11 – 75 kW EG Series Screw Compressors

Features11 – 75 kW EG Series Screw Compressors

Features

The EG series compressors represent a giant leap in design and performance with each component designed for reliability and ease of maintenance. The compressor is manufactured in compliance with applicable international standards (CE , ASME, UL and others) and designed as per the international quality standards. These new generation compressors significantly reduce operating costs and provide cost savings with fast return on investment .

Key features

- Eco-Friendly

- High Operator Safety

- Robust Construction with Reliability Built on Every Component

- Compact, Aesthetically Appealing and Easy to Install at Assembly Area

- Low Lifecycle Cost

- Energy Efficient

90-160 kW EG Series Screw Compressors

Features90-160 kW EG Series Screw Compressors

Features

The EG series compressors represent a giant leap in design and performance with each component designed for reliability and ease of maintenance. The compressor is manufactured in compliance with applicable international standards (CE , ASME, UL and others) and designed as per the international quality standards. These new generation compressors significantly reduce operating costs and provide cost savings with fast return on investment .

Applications

- Cement

- Textiles

- Paper & pulp

- Machine tool shops

- Steel making

- Food processing

- Automotive

Key features

- Oil carry over less than 1ppm

- Grouped service points ensure easy access to components for maintenance

- Optimized cooler design and cooling fans ensure low running temperatures

- Versatile neuron II micro controller provides easy diagnostics of system parameters

- Models available as bare units/side located drier/variable speed drive variants

- Energy efficient eta profile air ends & gear drive to reduce energy consumption

- Wide range of accessories – vertical air receivers, driers, automated supply side controller and variable frequency drives to meet diverse operating conditions

EG SERIES ROTARY SCREW - 11 - 250 KW/47 - 1612 CFM

FeaturesEG SERIES ROTARY SCREW - 11 - 250 KW/47 - 1612 CFM

90-250 KW Single-Stage Horizon

Features90-250 KW Single-Stage Horizon

Features

Applications

- Paper & pulp

- Machine tool shops

- Textiles

- Cement

- Automotive

- Steel making

- Food processing

Key features

- Oil carry over less than 2ppm

- Grouped service points ensure easy access to components for maintenance

- Optimized cooler design and cooling fans ensure low running temperatures

- Versatile neuron II micro controller provides easy diagnostics of system parameters

- Models available as bare units/side located drier/variable speed drive variants

- Wide range of accessories – vertical air receivers, driers, automated supply side controller and variable frequency drives to meet diverse operating conditions

EE75-EE160 Two-Stage Horizon

Features

EE75-EE160 Two-Stage Horizon

Applications

- Paper & pulp

- Machine tool shops

- Textiles

- Cement

- Automotive

- Steel making

- Food processing

Key features

- Oil carry over less than 2ppm

- Grouped service points ensure easy access to components for maintenance

- Optimized cooler design and cooling fans ensure low running temperatures

- Versatile neuron II micro controller provides easy diagnostics of system parameters

- Models available as bare units/side located drier/variable speed drive variants

- Wide range of accessories – vertical air receivers, driers, automated supply side controller and variable frequency drives to meet diverse operating conditions

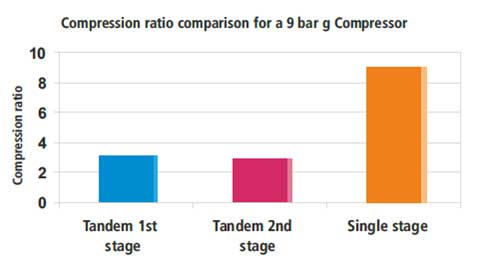

Ratio of Suction to Discharge of a Screw Airend:

A single-stage compressor, operating at a discharge pressure of 9 bar, has a compression ratio of 1:9 (Ratio of Suction to Discharge of a Screw Airend) .In a two-stage compressor operating at the same discharge pressure, the compression ratio is divided between the two-stages of tandem airend and is about 1:3 in each stage. This makes the airend more reliable and efficient due to smaller loads on the bearings. The volumetric efficiency of two-stage is better than single-stage compression.

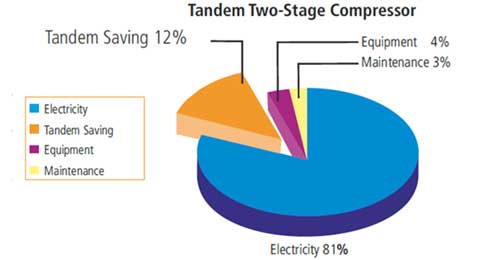

Energy Efficiency of Tandem Screw Compressors:

ELGi offers tandem screw compressors to help industries reduce their operating and energy costs. It is two-stage compressor, having energy efficiency as the key features. The compression is done in two-stages to improve the volumetric efficiency and thereby contributing to decrease in power consumption and increase in saving energy costs. Tandem air compressors consume 8-12% less power and offer a return on investment within 8-15 months when compared to single-stage compressors.

Trolley Mounted Compressors 185-1100 cfm

Features

Trolley Mounted Compressors 185-1100 cfm

Known for their reliability and ruggedness, ELGi portable compressors are available in single and two stage models to meet a wide range of applications like jack hammers, rock drills, impact wrenches, chipping tools and sand blasting.

Applications

- Cable laying

- Construction sites

- Mining

- Sandblasting

- CBM (Coal Bed Methane)/oil & gas exploration

Key features

- Energy efficient eta V profile air ends

- Highly reliable and works in the most demanding of work sites

- Complete range covering single stage models up to 250 psi and two stage models above 250 psi

- Centralized control panel for ease of use

- Select models available with international warranty on engines

- Easy maneuverability allows quick turns and climbing slopes

- Large access doors for ease of maintenance

- Tow bars designed for safe highway running. Single and multi-axle tow bar options available

- Industrial grade steel and powder coated canopy for maximum corrosion protection and durability

Skid Mounted Compressors 475 to 1500 cfm

FeaturesSkid Mounted Compressors 475 to 1500 cfm

This range of compressors are ideal for mounting on drill rigs or utility trucks and suited for applications like water well drilling. ELGi is one of the few companies in the world to offer the full line of single and two stage compressors in this range. ELGi compressors are widely used by drill rig OEMs globally.

Applications

- CBM/oil & gas exploration

- Construction & mining

- Water well drilling

Key features

- Forklift slots provided for ease of placing unit on a utility truck or drill rig unit

- Centralized control panel for ease of use

- Engines come with international warranty

- Large access doors for ease of maintenance

- Complete range covering single stage models up to 250 psi and two stage models above 250 psi

- Industrial grade steel and powder coated canopy for maximum corrosion protection and durability

- Energy efficient eta V profile air ends

- Highly reliable and works in the most demanding of work sites

OIL - FREE SERIES SCREW

FeaturesOIL - FREE SERIES SCREW 90 - 450 KW / 480 - 2515 CFM

Compressed air generated by air compressors contain inherent impurities that are detrimental to compressed air conveying and the end application. Some common contaminants of compressed air can be water, dirt, small wear particles, bacteria and sometimes even degraded lubricating oil. All these impurities mix together and often form an acidic sludge that might increase the wear and tear of end applications like pneumatic tools, machineries, valves orifices and electro pneumatic controls like relays etc.,Only compressed air that is totally clean and dry shall ensure reliable working of compressed air systems and maximise energy savings. ELGi offers a wide range of pneumatic downstream and upstream accessories that make the air friendly to the environment and end use. The air treatment downstream accessories offered by ELGi are called AIRMATE systems and energy conservation systems are classified as ELGi CONSERVE.

ELECTRIC PORTABLE (TROLLEY)

FeaturesELECTRIC PORTABLE (TROLLEY)22 - 75 KW /131-490 CFM

Compressed air generated by air compressors contain inherent impurities that are detrimental to compressed air conveying and the end application. Some common contaminants of compressed air can be water, dirt, small wear particles, bacteria and sometimes even degraded lubricating oil. All these impurities mix together and often form an acidic sludge that might increase the wear and tear of end applications like pneumatic tools, machineries, valves orifices and electro pneumatic controls like relays etc.,Only compressed air that is totally clean and dry shall ensure reliable working of compressed air systems and maximise energy savings. ELGi offers a wide range of pneumatic downstream and upstream accessories that make the air friendly to the environment and end use. The air treatment downstream accessories offered by ELGi are called AIRMATE systems and energy conservation systems are classified as ELGi CONSERVE.

131 to 490 CFM

Features131 to 490 CFM

Ideal for usage in mining and construction sites where electric power is easily available. These compressors offer the benefit of quiet and emission-less operation.

Applications

- Quarry, Industrial air (standby), Construction & breaker, chipping hammers, cleaning, concrete boom pumps, diaphragm pumps

Key features

- Automatic star delta starter provided

- Products available from 22- 75kW

- Quiet and emission free operation

- Industrial grade steel and powder coated canopy for maximum corrosion protection and durability

- Centralized contactor based control panel with 220V starting contactor

- Tow bars designed for safe highway running

- Centralized control panel for ease of use

- Energy efficient eta V profile air ends

- TEFC squirrel cage motors with class F insulation

- Easy maneuverability allows quick turns and climbing slopes

- Large access doors for ease of maintenance

OIL - LUBRICATED RECIP 1.0 - 40 HP / 2 -128 CFM

FeaturesOIL - LUBRICATED RECIP 1.0 - 40 HP / 2 -128 CFM

Compressed air generated by air compressors contain inherent impurities that are detrimental to compressed air conveying and the end application. Some common contaminants of compressed air can be water, dirt, small wear particles, bacteria and sometimes even degraded lubricating oil. All these impurities mix together and often form an acidic sludge that might increase the wear and tear of end applications like pneumatic tools, machineries, valves orifices and electro pneumatic controls like relays etc.,Only compressed air that is totally clean and dry shall ensure reliable working of compressed air systems and maximise energy savings. ELGi offers a wide range of pneumatic downstream and upstream accessories that make the air friendly to the environment and end use. The air treatment downstream accessories offered by ELGi are called AIRMATE systems and energy conservation systems are classified as ELGi CONSERVE.